Rustoleum Rock Solid Clear Coat Dry Time

A second coat of rocksolid floor coatings can be applied.

Rustoleum rock solid clear coat dry time. Clear polycuramine top coat garage floor kit offers unsurpassed durability. Surface should be ready for foot traffic in 8 10 hours and vehicle traffic in 24 36 hours depending upon temperature and humidity. Traditional solid stains require two coats to fully hide the wood grain underneath. Do not coat the floor if it is raining or if extremely damp conditions exist.

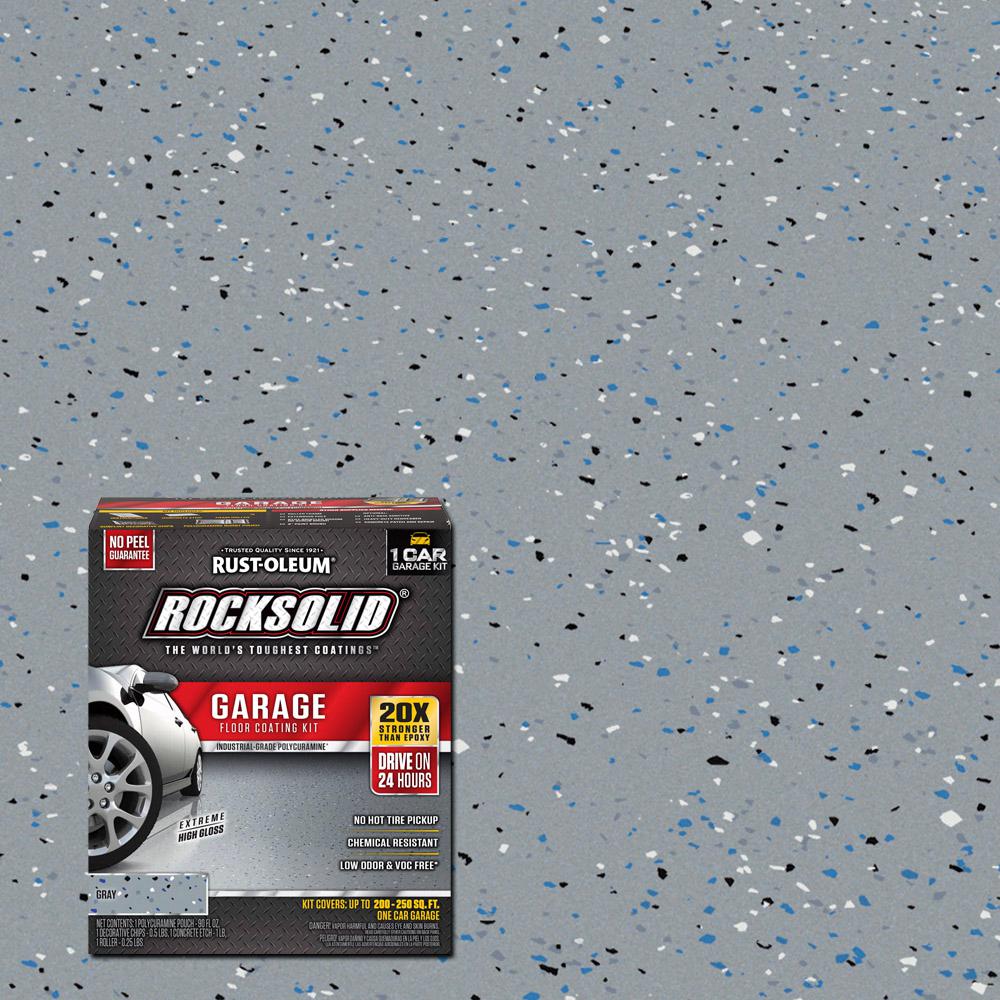

Unique polycuramine clear high gloss formula is 20 times stronger than epoxy. Do not walk on coating while it is still tacky. Rust oleum rock solid clear coat. Rocksolid 6x deck coat is a solid deck resurfacer that is 6x thicker than traditional solid stains.

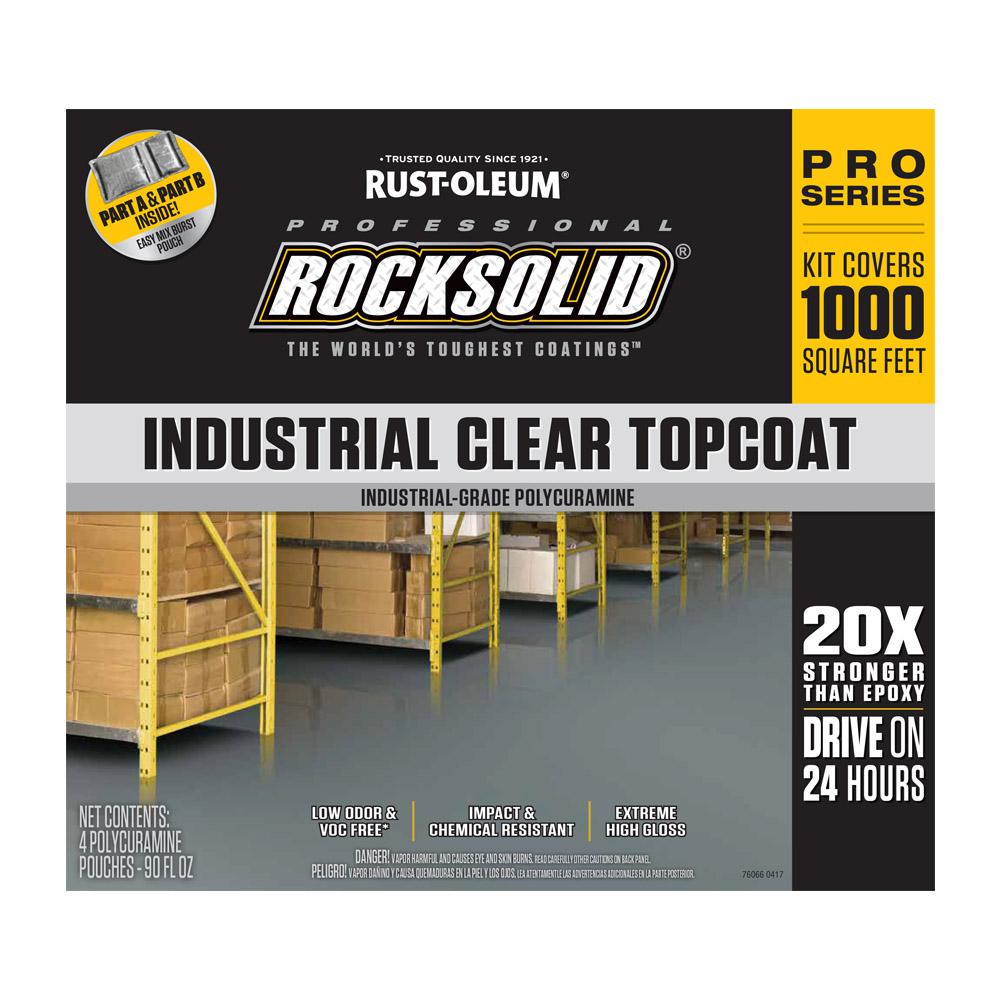

Extreme cold application temperatures may slow the cure time. Apply no earlier than 8 10 hours after coating with rocksolid garage or metallic floor coating and within 7 days. Ensure the surface is clean and dry prior to application. Antislip for a non slip finish use rocksolid anti slip.

Allow unused product to harden in container and discard. The box says 400 500sqft cover for a 2 5 car garage. 3 8 nap roller cover for clear top coat nitrite gloves. The floor can be recoated after 8 12 hours and before 7 days without sanding the surface for proper adhesion of the second coat.

Rocksolid 6x deck coat is formulated to produce a beautiful finished look in just one coat allowing you to complete your deck in one day. Rust oleum rocksolid 90 oz. Dry time temperature and humidity may affect drying time. If applying the clear coat over a heavy chip broadcast pour the contents into a standard paint tray rather than directly onto the floor.

Temperature and humidity may affect drying time. We had a few bubbles pop up in our coating during dry time and after some research learned it was probably due to the 40 50 degree temperature swings we were having while i applied. If more than 7 days has passed sand the surface with 60 80 grit sandpaper before applying the second coat. Follow the directions on both simple as that.

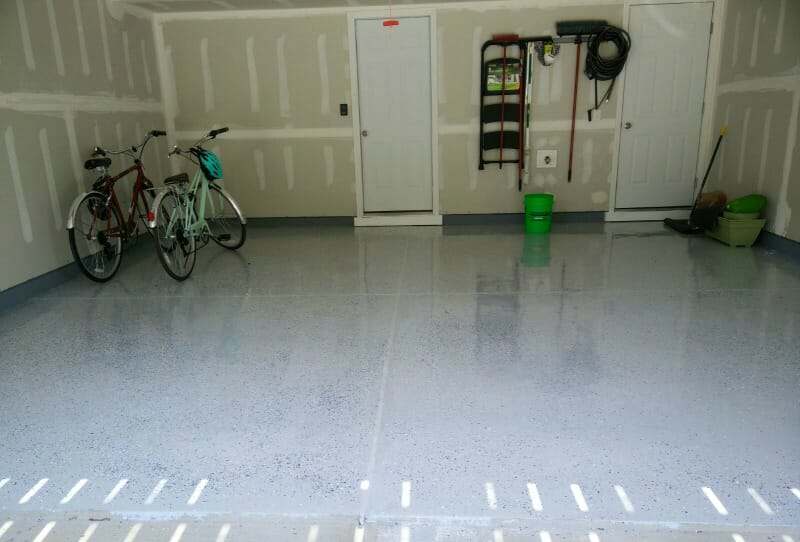

Once a small amount of the garage coat is poured onto a section of floor use the foam roller included to roll it out in an m and w pattern working in 4 x 4 sections. Optimal installation temperature is 55 90 f 13 32 c. Resists salt oil gas and other harsh chemicals this is one of the toughest floor coatings available. Etch then moisture block and dry again.

Ensure the coating is not tacky prior to recoat. For clear topcoat applications over newly coated surfaces the coating will need to be dry to allow foot traffic do not walk on coating while it is still tacky. So just check the weather for the few days you plan to work on. Heat the instructions say 40 90 f but i wouldn t recommend anything less than 60 cure time goes way up and you risk moisture issues.

This time of year you can t do this without heat. Do not walk on the coating while it is still tacky.