Pointed Roof Support

To hold them up until the decking of the roof is placed on top a 12 foot 1 inch by 4 inch piece of lumber is used.

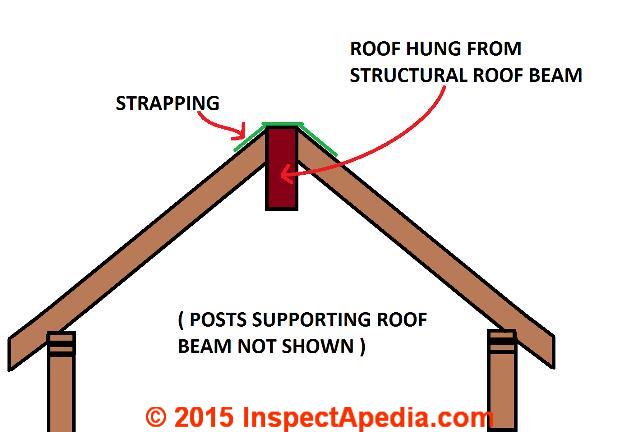

Pointed roof support. Manufactures roof supporta that save time and money and give roof maintenance workers better safer rooftop access to equipment. A composite decking made of solid materials it resembles real wood and particularly strong and stable for bearing heavy load. You may have noticed that the roof framing for the gazebo above does not have a center support post to hold up the peak apex of the roof where all the rafters come together. Usages vary slightly from region to region or from one builder or architect to another.

When all the trusses are installed and the first row of decking is on this brace is removed. The personal proximity detection system is specifically designed to address this issue and reduce injuries to longwall equipment operators. The rooftop support systems rts division of eberl iron works inc. Our economical and labor saving designs which include roof pipe supports roof mounted duct supports access ramps maintenance platforms.

Usually trusses are put 24 inches apart. Roof terminology is also not rigidly defined. Roof shapes differ greatly from region to region. It can be nailed temporarily to each truss as the next truss is put in place.

Promixity detection for powered roof supports as technologies allow operators to be moved further from the face it sometimes means that an operator is not always visible to other mine personnel. The main factors which influence the shape of roofs are the climate and the materials available for roof structure and the outer covering. Typically a post would be needed to prevent the weight on the rafters from splaying out the tops of the walls.