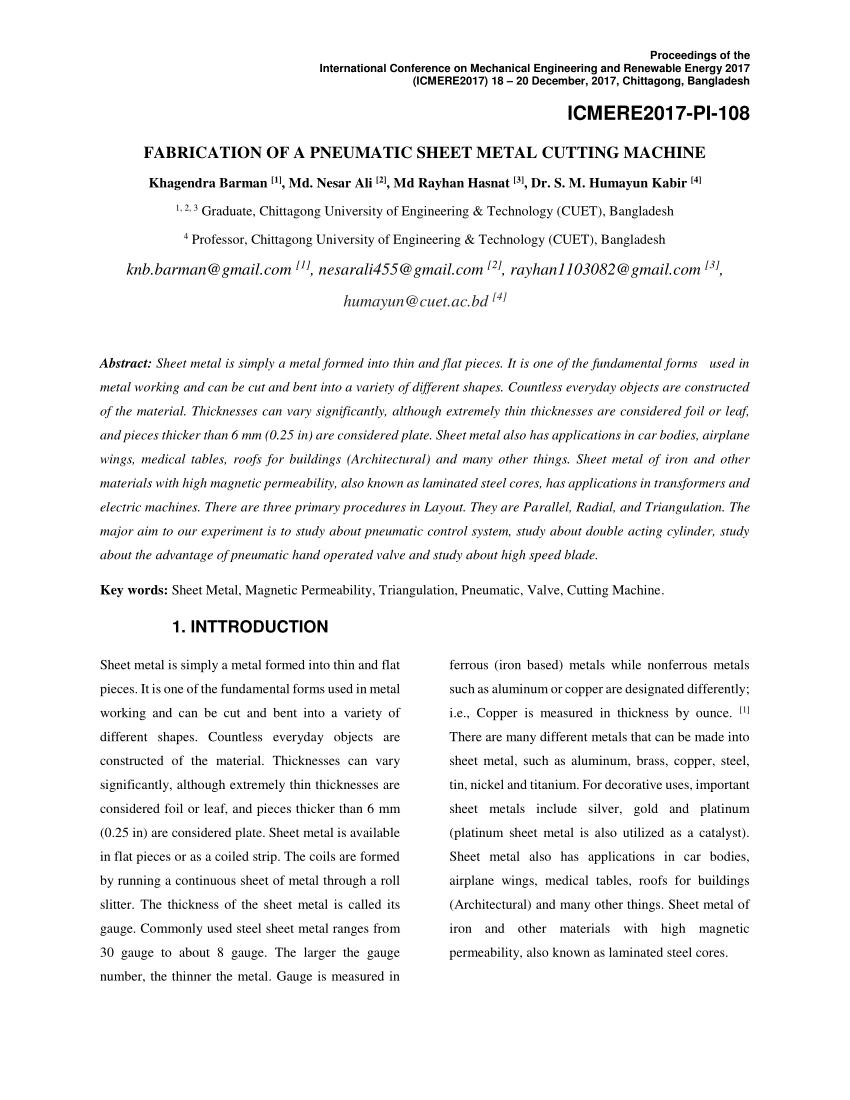

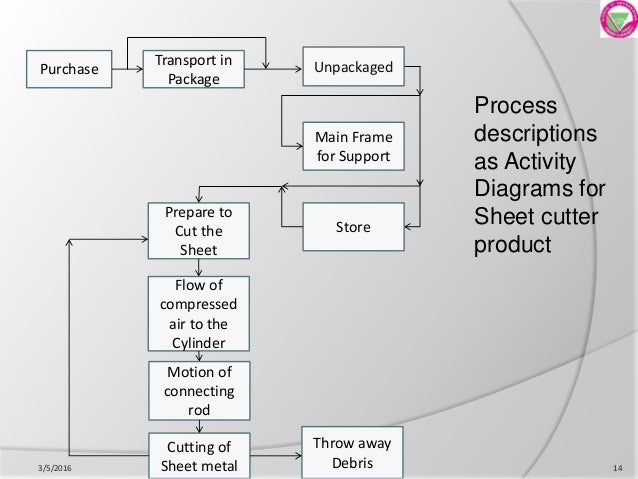

Pneumatic Sheet Metal Cutting Process

The heat from the torch this weakens the sheet metal under the torch and allows it to be blown away with high pressure air.

Pneumatic sheet metal cutting process. This system is used to shear the aluminum sheets of various thicknes. Info profiilikeskus fi teppolantie 4 fi 90440 kempele finland tel. After reading this article you will learn about 1. Blanking is a cutting process in which a piece of sheet metal is removed from a larger piece of stock by applying a great enough shearing force in this process the piece removed called the blank is not scrap but rather the desired part blanking can be used to cutout parts in almost any 2d shape but is most commonly used to cut workpieces with simple geometries that will be further shaped.

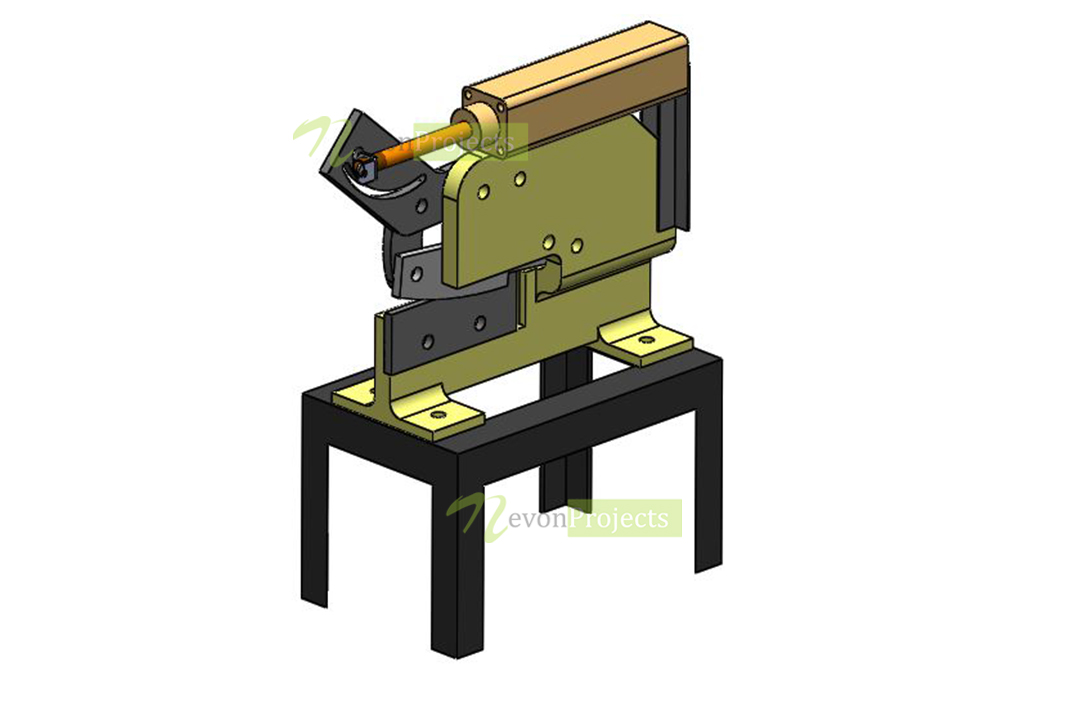

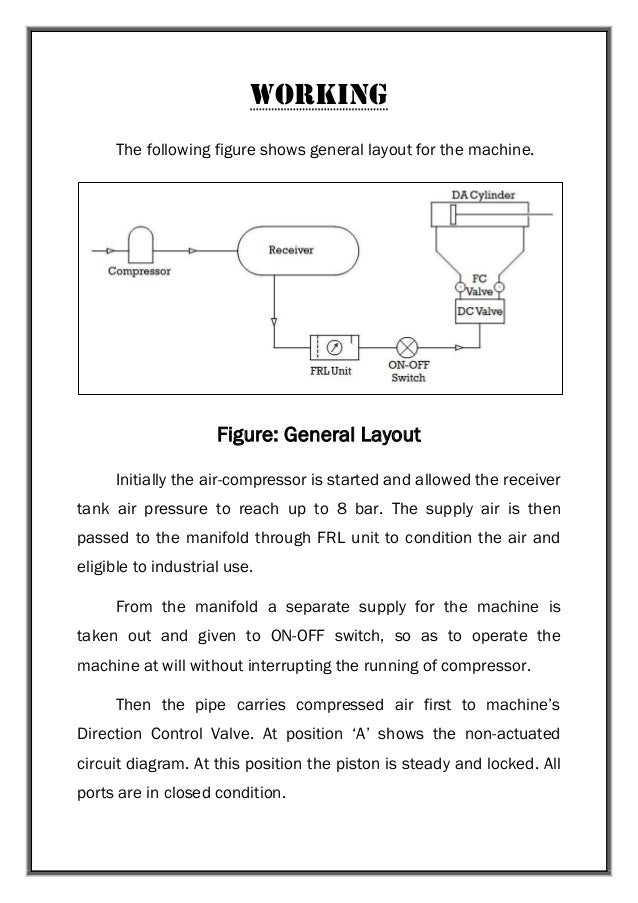

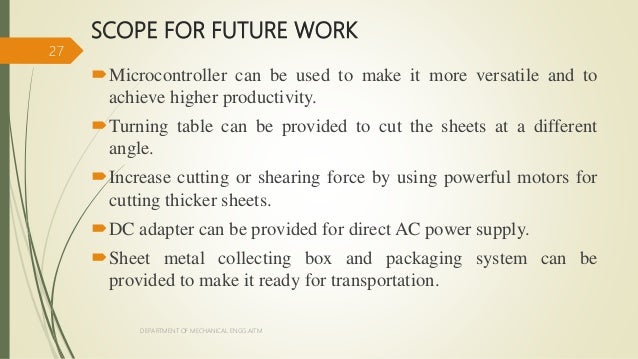

In addition special sheet metal cutting tips are available for specific metals and thicknesses. It is a manual method so that sheet metals are to be wasted sometime because of mistakes happened such as wrong dimensions etc and also even a simple cutting may take long time hydraulic machines are also available for sheet metal cutting. So here we propose a pneumatic based cutting machine that uses pneumatic strength for instant cutting of small sheets and pipes. Pneumatic sheet metal shearing cutting machine synopsis.

Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes countless everyday objects are fabricated from sheet metal. Sheet metal forming basics. Manual cutting machines require a lot of manual effort and also are not suitable for bulk cutting processes with accuracy. The process of blanking or cutting the flat pattern from a sheet metal can be achieved by a variety of methods.

Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered. On time delivery increased productivity in your manufacturing process and 100 after sales commitment these are not just goals for us this is the way we do business. History of metal cutting 3. But this method is used for only heavy metal cutting and its cost is very high we are using a.

Metal cutting is the process of removing unwanted material in the form of chips from a block of metal. Sheet metal is metal formed by an industrial process into thin flat pieces. Compressed air is used in most of the machines and in some cases compressed carbon dioxide whereas cutting process is become easy. With the use of the industrial manufacturing process sheet metal is formed by working metal into flat and thin pieces sheet metal is one of the very convenient ways that is used in metal working and it can be mended and cut into various shapes and dimensions.

Fast cutting action is carried out. Thicknesses can vary significantly. We are using scissors for simple sheet metal cutting. Cutting process is involved in almost every industrial process.

Cutting without bending is achieved. Types of cutting processes 4. Meaning of metal cutting.